The KT 1.5 is a crash tabber in which the edge of the piece to be tabbed is fed into the machine first. That edge contacts the tab which has fed down in front of the piece, pulling the tab from its backing paper. The tab and the piece then crash into a sweep and roller system that folds the tab neatly and tightly to the piece.

Advantages of Crash Tabbers:

- High productivity. The shortest dimension feeds through the machine increasing production rates at any given speed.

- Simplicity. Short paper path with no skewing adjustment etc.

- Accuracy. Tabs fold tight to the edge of the piece and do not drift from left to right.

- Ideal for off line application.

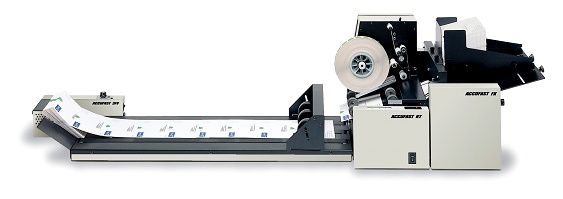

KT 1.5 Tabber, FX Feeder and 3FV Conveyor

The ACCUFAST KT is a feature rich basic tabbing machine. It uses plain circular or rectangular tabs either opaque or clear. It tabs pieces up to ¼” in thickness and it rolls the waste up on a take up spool. It applies 1 inch or 1.5 inch tabs at speeds of 15,000 per hour or so, it is a stretch to refer to the ACCUFAST KT as a basic tabber – there’s a lot of the professional in the KT.

- Applies 1 tab per piece

- Tabs 15,000 pieces per hour

- Tabs pieces 5” to 12” wide, from 20 lb. thin 1/4” thick, coated and uncoated

- Runs a variety of 1” and 1.5” tabs: paper & clear, circles & rectangles, on rolls with or without tractor holes

- Built-in waste take-up spool

- 5,000 one inch and 4,000 1.5 inch tabs per roll.

- Weighs 47 pounds

- Measures 10”l x 17”h x 21”w

- Uses 115 volts 2 amps 60 hz or230 volts 1 amp 50 hz

- Goes in-line with ACCUFAST and other tabletop Labelers and Printers

- Its outstanding feature is its ability to run both 1 and 1.5 inch tabs at the flick of a switch.

Specifications:

Click image for video demonstration.

PAC

INCORPORATED

TY

YOUR PREMIER SOURCE FOR MAILROOM AND PACKAGING EQUIPMENT

1 800 356-8964

Call for information

and quotes

Email: [email protected]

Click here for the brochure of the Accufast KT

Accufast KT Tabbing Machine